I want to start by saying happy new year to you all and I hope you have a great 2016.

Over the last year and a half I have been working full time as a cabinet maker, primarily making fitted interiors, as well as free standing furniture. During this time I haven't done much of my own work. During this next year I want to do more of my own work to enhance my portfolio of work and develop my design and problem solving skills. The type of work I want to make is more smaller, free standing pieces of furniture, small runs of products which can be batched out and small pieces of fitted furniture.

My first job of the year is to make a couple of radiator covers which will be painted and instaled as a fitted piece of furniture. I am also in the process of making a chess board, this was more of a self indulgence piece, as I have always wanted to make one.

In the months running up to Christmas I was asked by my partner to make her a bath tray, a tray which rests across the bath to hold soaps and shampoo's while in the bath, and after making her one, she was asked by several people 'where do you get them from.' From these comments I started to make a small batch and began to sell them on Etsy and had great success selling them all.

I am looking forward to see what 2016 will bring and I am now looking forward to get back in the workshop to make some shavings.

Josh

Over the last year and a half I have been working full time as a cabinet maker, primarily making fitted interiors, as well as free standing furniture. During this time I haven't done much of my own work. During this next year I want to do more of my own work to enhance my portfolio of work and develop my design and problem solving skills. The type of work I want to make is more smaller, free standing pieces of furniture, small runs of products which can be batched out and small pieces of fitted furniture.

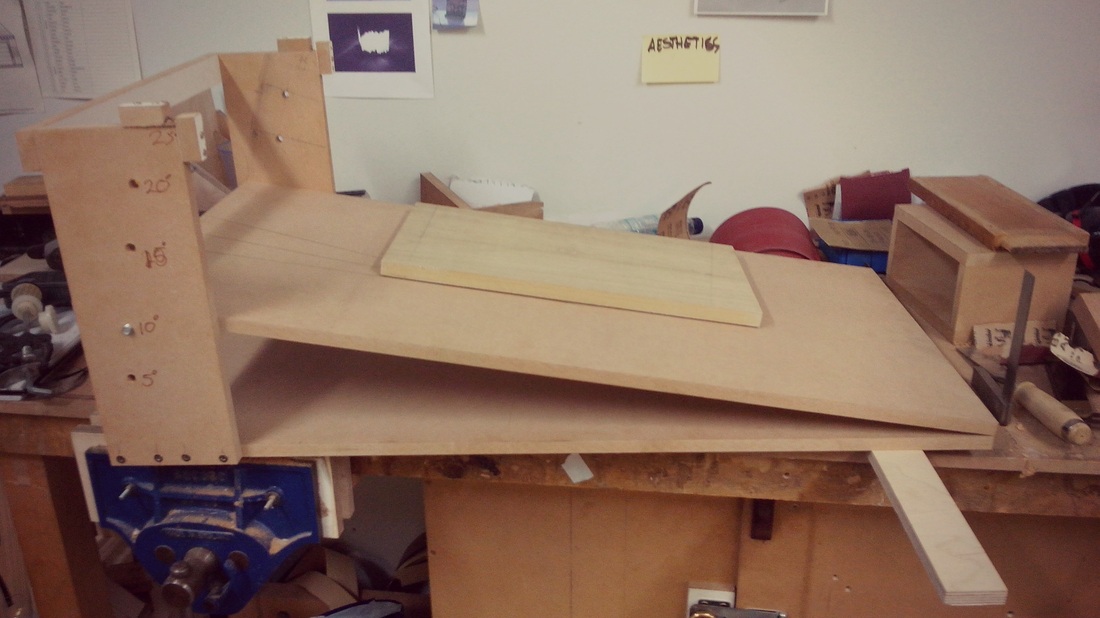

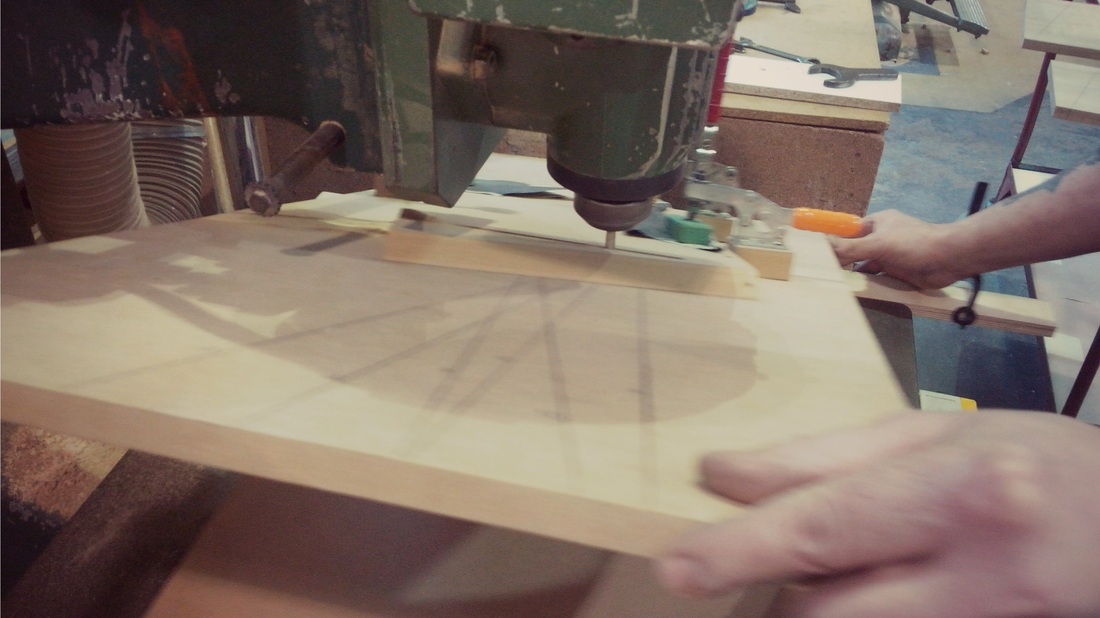

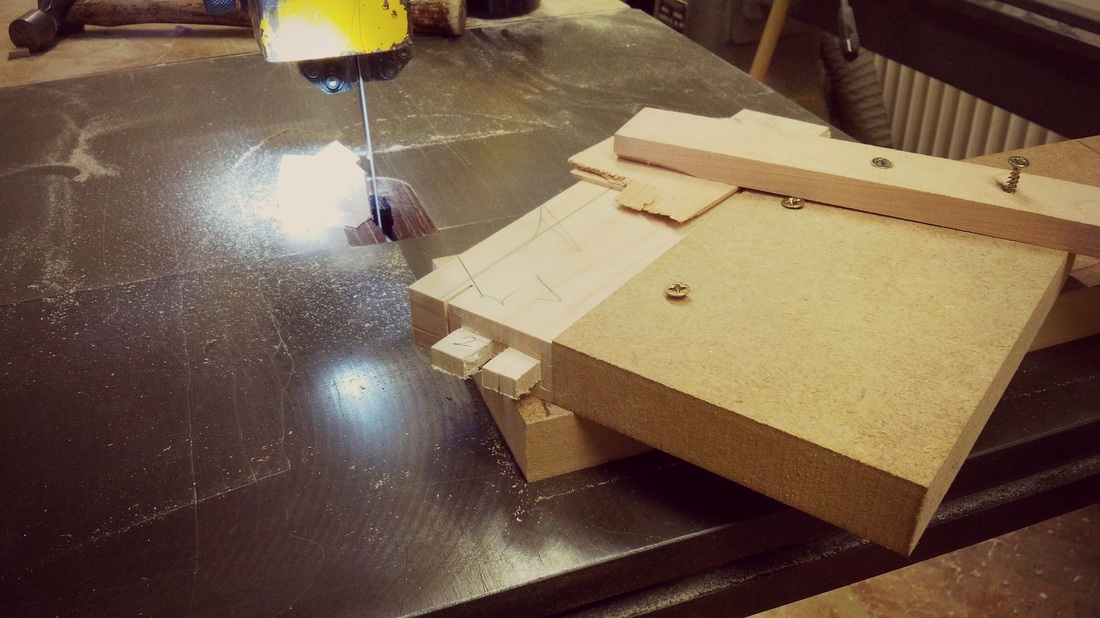

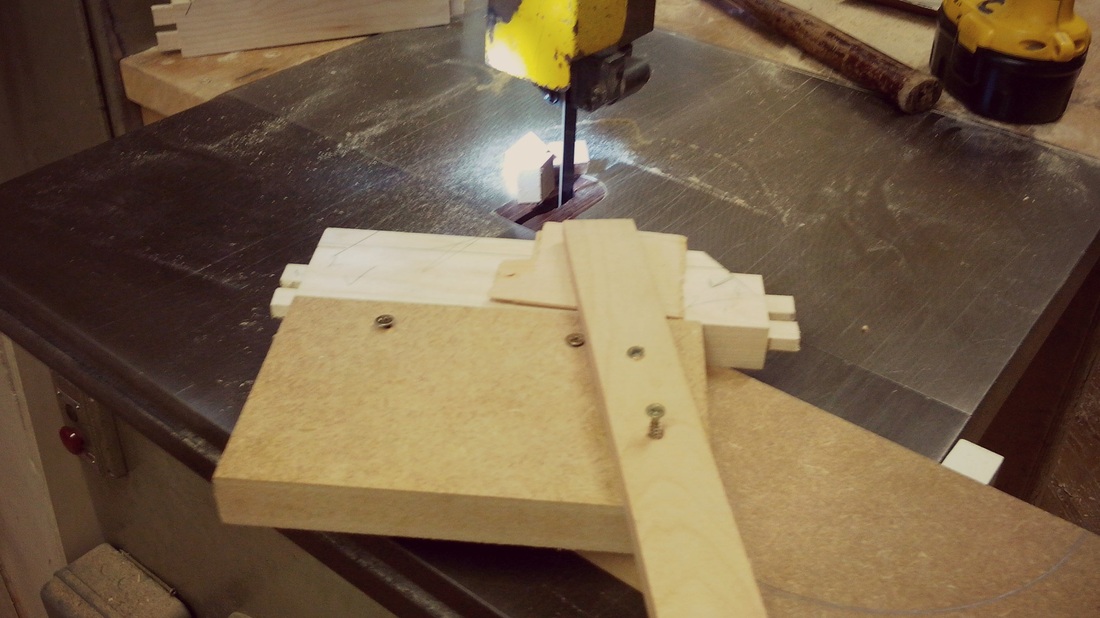

My first job of the year is to make a couple of radiator covers which will be painted and instaled as a fitted piece of furniture. I am also in the process of making a chess board, this was more of a self indulgence piece, as I have always wanted to make one.

In the months running up to Christmas I was asked by my partner to make her a bath tray, a tray which rests across the bath to hold soaps and shampoo's while in the bath, and after making her one, she was asked by several people 'where do you get them from.' From these comments I started to make a small batch and began to sell them on Etsy and had great success selling them all.

I am looking forward to see what 2016 will bring and I am now looking forward to get back in the workshop to make some shavings.

Josh

RSS Feed

RSS Feed